Aluminium plates and SS 316 perforated sheets are two important materials that are utilised in many sectors because they are very strong, flexible, and long-lasting. Both materials are recognised for their outstanding performance in a wide range of uses, from building things to making cars to making things seem nice. This article goes into detail on the properties, uses, and advantages of various materials, focussing on how they fit into the world of modern manufacturing.

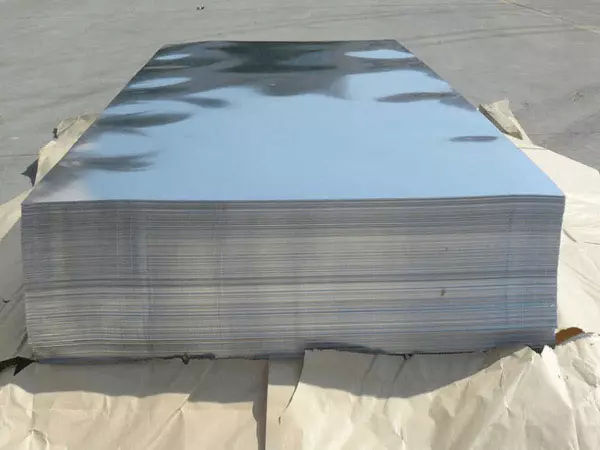

What is an aluminium plate?

Metal plates are flat, solid sheets composed of very pure metal. People recognise them for being light, strong, and very resistant to rust. Because they can handle tough conditions, these plates are utilised a lot in fields including aerospace, construction, and automotive. Aluminium plate are also quite malleable so that they may be readily moulded and welded into complicated shapes.

A Closer Look at SS 316 Perforated Sheets

Another important material utilised in contemporary production is SS 316 perforated sheets, which are constructed of high-quality stainless steel. SS 316 perforated sheets are great for use in severe locations since they don’t rust or discolour easily. The holes in the sheets let you be creative with their design so that they may be used for a wide range of things, from attractive facades to useful screens in factories.

Looking at the differences between aluminium plates and SS 316 perforated sheets

Aluminium plates and SS 316 perforated sheets are both strong and long-lasting, although they serve distinct purposes. Because they are lighter and stronger than other materials, aluminium plates are often used for lightweight applications. SS 316 perforated sheets, on the other hand, are great for uses where they need to look good and resist corrosion.

Aluminium plates are great for sectors like aerospace, where weight and strength are important. SS 316 perforated sheets are great for architectural designs and industrial operations where exposure to the environment or harsh chemicals is a worry. Both materials offer unique benefits that make them necessary for contemporary design, building, and production.

Uses for aluminium plates

Aluminium plates are useful in many sectors since they can be used in so many ways. Aluminium plates are used in the car industry to make lightweight pieces for the body of the car. These parts enable the car to have better gas mileage without losing strength. Also, aluminium plates are used to create roads, bridges, and buildings since they are strong and can be bent.

How SS 316 Perforated Sheets Can Be Used in Many Ways

Architects use SS 316 perforated sheets a lot because they are strong and look good. These perforated sheets are widely used to create homes and businesses. They may be used for beautiful facades, privacy screens, or ventilation panels.

Advantages of Using SS 316 Perforated Sheets and Aluminium Plates

Manufacturers and engineers may benefit from both aluminium plates and SS 316 perforated sheets in a number of ways. The main advantages are:

- Robust yet light:Aluminium plates are very robust and light, which makes them great for situations where weight is important. SS 316 perforated sheets are heavier yet stronger, making them great for tough jobs.

- Corrosion Resistance:SS 316 is well-known for not rusting, particularly in corrosive and marine settings. Aluminium plates are likewise resistant to corrosion, although not as much as SS 316.

- Flexibility in Design:Both materials are flexible, making it simple to customise them. Aluminium plates and SS 316 perforated sheets may be made to fit your needs, whether you want to use them for ornamental purposes or utilitarian ones.

- Durability:Both materials are regarded as being quite durable, which means they don’t need to be replaced as often in industrial and architectural settings.

Conclusion

Aluminium plates and SS 316 perforated sheets are very important in contemporary production because they have unique qualities and may be used in many different ways. These materials are the best for any project, whether it’s erecting a building facade or working on an aircraft project. Go to Dinco.ae to learn more about where to get these products for your next project.

FAQ

- What are the primary differences between aluminium plates and SS 316 perforated sheets?

Aluminium plates are lighter and more malleable, while SS 316 perforated sheets offer superior corrosion resistance and strength, making them suitable for harsh environments. - Can aluminium plates be used in marine applications?

Yes, aluminium plates can be used in marine environments, though SS 316 perforated sheets offer better corrosion resistance, making them the preferred choice for harsh conditions. - What industries use SS 316 perforated sheets?

SS 316 perforated sheets are commonly used in industries such as architecture, construction, food processing, and chemical manufacturing due to their corrosion resistance and aesthetic appeal. - Are aluminium plates more affordable than SS 316 perforated sheets?

Generally, aluminium plates are more affordable than SS 316 perforated sheets, as they are made from a less expensive material and are easier to manufacture. - How do I choose between aluminium plates and SS 316 perforated sheets for my project?

The choice depends on the specific needs of your project. If weight and ease of fabrication are important, aluminium plates are ideal. If you need corrosion resistance and durability in harsh environments, SS 316 perforated sheets are the better option.